When diving into oilfield operations, the topic of fines migration is inevitable. These tiny particles shift within our reservoirs due to drag effects.

Controlling this particle movement is crucial because it directly impacts production efficiency. Unchecked migration can obstruct oil flow, making operations costly and less efficient.

Understanding Fines Migration: A Closer Look

-1.png?width=400&height=350&name=PANTHER_Pic(1)-1.png)

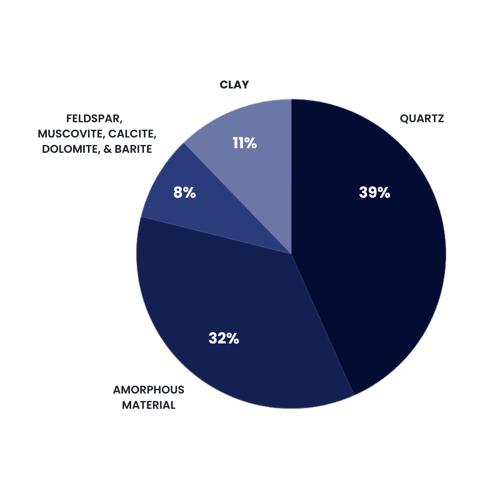

Fines in oilfields refer to particles that move within the reservoir during production. These particles can be composed of:

- Clays (often <4 microns).

- Silts (4-64 microns).

The significance of these specific micron sizes?

They correlate with the reservoir rock’s pore sizes. Understanding the size of particles allows:

- Prediction of potential movement or blockages.

- Insights into the effect of the particles on fluid flow.

- Strategy development for treatments based on particle size to optimize productivity.

In a nutshell, knowing the micron size offers a lens into the reservoir’s nature, paving the way for informed decisions.

The Risk of Ignoring Fines Migration

Ignoring fines migration isn’t a risk worth taking. Why? Migrating fines can create a series of problems, such as:

- Obstruction of the pore throats near the wellbore.

- Diminishing well productivity.

- Inducing formation damage, particularly in sandstones.

One of the trickier aspects is that the signs can be quite subtle. For example, you might only notice a gentle dip in productivity initially. But that can be a red flag signaling a buildup of fines close to the wellbore.

Why is Fines Migration Significant?

Fines migration is far from mere academic chatter. It’s pivotal to the life cycle of oil and gas wells. This particle movement influences a well’s longevity, productivity, and overall health.

Without a clear handle on fines migration, you’re looking at:

Reduced Productivity: As these fines journey and settle, they can obstruct essential pathways, which affects fluid flow and can decrease oil and gas output.

Higher Operational Costs: More fines? More problems. This means regular maintenance, well interventions, and costly repair jobs.

Wellbore Stability Concerns: A buildup of fines can jeopardize the wellbore’s structural integrity, increasing risks like collapses.

Bottom line? Stay on top of your fines. Prioritize their effective management. It’s not just about ramping up output, but also about ensuring a safe, efficient operational landscape.

The Role of Clay in Fines Migration

When we talk about fines migration, clays are often center stage. But here’s something you might find surprising: just because a reservoir has a lot of clay doesn’t mean it’s automatically prone to water sensitivity.

While mobile fines are inclusive of clay, their composition encompasses a mix of different minerals. This means that a clay-rich reservoir might not always be a hotbed for water-related problems. The other minerals play their part, too, reacting with fluids and shaping fines migration patterns and overall reservoir behavior.

The Challenge with Clay Swelling-1.png?width=400&height=376&name=PANTHER_Pic(3)-1.png)

Within the complexities of oilfield operations, clay swelling emerges as a significant concern. Envision the delicate balance of clay being disrupted in the formation, leading to:

- Reduced formation permeability.

- Altered clay stability.

Often, drilling fluids inadvertently exacerbate the issue, especially when interacting with the formation. Notably, clays located in the larger pores of reservoir rocks may resist fluid flow more strongly.

Such swelling can increase well construction costs and introduce various operational hurdles.

However, it’s crucial to differentiate between types of drilling fluids. While water-based solutions are favored for their environmental advantages, they sometimes can inadvertently be the cause of:

- Hole constrictions or even complete blockages.

- Buildup of thick cutting beds.

- Slower drilling speeds.

By thoroughly understanding the dynamics of clay swelling, we can develop effective clay inhibitors that address the issue while upholding environmental standards.

In essence, proactive management of clay swelling is pivotal for streamlined oilfield operations. Armed with the right expertise and resources, we can navigate this challenge, ensuring both fluidity and efficiency in the drilling process.

Clay Control Solutions: The Need for Clay Stabilizers-1.png?width=480&height=349&name=PANTHER_Pic(4)-1.png)

At certain wellsites, the importance of clay stabilizers cannot be overstated. Consider these oilfield chemicals as the unsung heroes in well stimulation treatments. Their primary function? To make sure that clay particles stay put when they come in contact with water-based fluids.

By fine-tuning the electrolytic properties and electrical charge of the treatment fluid, clay stabilizers ensure that clay fragments remain immobile. Without this intervention, free-moving clay fragments might compromise operational efficiency by obstructing the formation structure.

How Clay Stabilizers Work at the Molecular Level

To grasp the intricate workings of clay stabilizers, one must venture to the molecular realm. These agents do more than merely maintain equilibrium; they modulate the electrical dynamics of clay particles. This refined manipulation governs the behavior of clay fragments when exposed to treatment fluids—an essential consideration in well workover projects.

And the significance of this? Clays, along with certain sedimentary rocks, can pose considerable challenges during drilling, often the culprits behind issues like drill bit wear or even corroded casings.

Best Practices for Reducing Fines Migration with Clay Control Solutions

- Selecting the Right Clay Stabilizer

What to Consider: Establish the clay type, drilling environment, and pH levels. Each well has distinct conditions, so customization is essential. - Optimizing Application Methods

Timing is Everything: Determine whether to introduce stabilizers pre-treatment or during operations. Also, zero in on the right dosage and application points. - Monitoring and Adapting

Stay Alert: Monitor the performance of your stabilizers closely. Harness real-time insights to enhance your approach. - Incorporating Supplementary Techniques

Extras to Consider: Use solid control equipment to screen out larger fines. Stay informed about the newest drilling fluids to boost wellbore stability.

In our ever-evolving industry, clay stabilization remains a cornerstone. Given the rising environmental standards and the drive for cost-effectiveness, it’s essential for us to be on top of the best clay control methods. Our aim? Operations that are both efficient and sustainable.

The Panther Companies: Fluid Management Masters

When it comes to managing fluids in oil and gas production, The Panther Companies stands out as a leader. With a rich legacy in drilling fluids, solid control equipment, and an array of essential services, including haul-off and disposal, we bring together the best of all worlds.

How do we elevate our services? By fusing them all together. This integrated approach enables a total drilling fluid management system tailor-made for your unique well conditions.

Panther Production Pack Series: Zeroing in on Clay Control

The highlight in our suite of solutions is the Clay Control Panther Production Pack product line. Here’s a peek into what it offers:

Purpose: Crafted to address swelling clays in the fracture network.

Function: Designed to curb fines migration, safeguarding the fracture network’s integrity.

Mechanism: Dive a bit deeper, and you’ll find:

- Electronically optimized substituents that bond with clays, anchoring the molecule and initiating the encapsulation.

- A distinct biopolymer backbone ensuring clay swelling and fines migration are kept in check.

Benefits? They’re transformative:

- Ensures a robust fracture network.

- Cuts downtime, amplifying production longevity.

- Delivers aggressive results, the gold standard for oilfield operations.

Why Choose Panther Production Pack?

Clay control is undeniably the linchpin in successful, efficient oilfield operations. With the mounting challenges, it becomes imperative to employ solutions that aren’t just effective but revolutionary. Enter: Clay Control Panther Production Pack. Its unique mechanism is geared for unmatched efficiency in managing clay swelling and fines migration.

Experience unparalleled efficiency and longevity in your oilfield operations with our Clay Control Panther Production Pack product line. The future of aggressive and effective clay control is here. Embrace it today and witness a transformative change in your oilfield operations.